MRP System Adoption For MKP Group Ltd

After initially selecting 123insight for Maine Office Furniture in 2006, MKP Group decided to use the same MRP system to drive specific projects such as manufacturing a storage system for the British Library. The projects went well, so much so that 123insight was rolled out across the entire facility without considering other systems, with a case study following shortly afterwards. This ‘10 Years On’ case studies explores how 123insight has allowed MKP to drastically increase their product range whilst reducing both lead times and stock.

Lead times more than halved with MRP software

- Massively increased product range

- Reduced stock-holding

- Now used across two companies within the group, including the parent company

- Quality of products improved

- Training Assurance spreads the cost of training new staff

- Seamless update process

- Plan to expand with CRM+

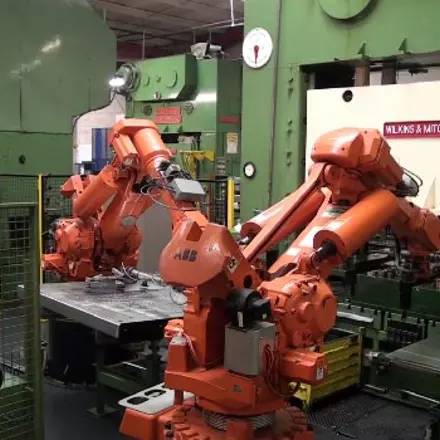

MKP Group, based in Milton Keynes, Buckinghamshire, comprises of Milton Keynes Pressings and Maine Office Furniture. 2006 saw the initial implementation of 123insight at Maine, replacing a discontinued MRP system. MKP saw the success, adopting the system for specific projects in 2013. A case study written at the time highlighted reductions in stock and far fewer errors, and shortly afterwards the decision was made to expand 123insight’s reach across the entire company. Maine has a staff of 25, with MKP employing approximately 175.

Researching MRP

Said Adrian Cook, MD; “We looked at the market in 2006, came across 123insight, liked the business model of paying a monthly subscription and that's when we took it on. Since then MKP has started to use it across the board.”

After 123insight was implemented across the whole of MKP significant benefits immediately came to light. Previously the company had a limited, fixed range of products, most of which were made from stock. Now that they have greater visibility of product sales trends and manufacturing capacity they have been able to widen their product range considerably. Adrian noted; “Originally we only had one product range - files and cupboards. We have five product ranges now. We manufacture pedestals and tower units, and we are diversifying into new products all the time.”

Products increased/stock reduced

Despite the massive increase in manufactured product types, stock actually reduced, which Adrian attributes to this visibility; “Before, we would have kept everything in stock in large quantities. We would also have held large quantities of pre-made components. Now we make everything straight to order rather than keeping stock.”

In addition to the reduction in stock and wider product range, lead times were more than halved, as only products that were actually sold were being manufactured; “By reducing our stock levels and only ordering what we need, we know straight away what the lead time is for the part so we can give accurate times to our customer at order placement.”

Product quality improvements

Something that was not expected was that the quality of the finished components improved as a byproduct of the streamlining process. Adrian explained; “We no longer have large amounts of stock, so the potential for damage to that stock, such as it getting dirty or being damaged by an operator has gone. Now, it's manufactured and within minutes or hours its moved to the next point on the assembly line, processed and dealt with.”

When MKP wanted to look at an MRP system we started off with the project and then moved onto implementing it across the company. We didn’t even go elsewhere - straight away the decision was that we’d go with 123insight.

Licencing flexibility

Since MKP implemented the system, 123insight’s reach has extended throughout the business. They increased from the initial 7 licences in use at Maine to another 6 at MKP. 123insight’s flexible licencing allows the group to add or remove licences on a monthly basis as and when they need them. Adrian noted; “Originally we only had our sales/support and ordering staff on 123insight but now we’ve got everybody within the management of the business using it. Our design team also have a seat.”

As a user of 123insight for over a decade, MKP has received several software updates, which they now opt to have installed remotely by 123 Insight at a time suitable to them. Adrian cites that the experience has been painless; “Updates were smooth. We agreed a time for it to happen, 123 Insight connected to us remotely upgrade the software. We were up and running the next day - there was no stopping of the business.”

Technical support

Support is important for any system relied upon by a company, and MKP and Maine combined are under 123insight’s average of one call to the Help Desk per customer per month, with all calls being completed to Adrian’s satisfaction; “Occasionally I've had to ring them up. They’re always helpful and if I can't get an answer straight away I know someone will ring me back within a few hours with the information I require.”

MKP has also taken advantage of 123 Insight’s Training Assurance, which allows them to purchase a fixed number of training days at a concessionary rate, spreading the cost as low monthly payments. Adrian says this has been very beneficial in ensuring that the workforce gets the most out of the system without having to think about budgeting for training; “We took Training Assurance around 2-3 years ago to spread the cost over the months so that we knew that we had the days in the bank and we could use them as and when we wanted to. The second after you think 'I need some training' the next question is usually 'how much will it cost'. Now we don’t have to even think about the cost... You're taking it out of the bank - it's like a savings account.”

Supplier relationship

As a long-standing user, Adrian values the relationship that he has built up with 123 Insight. It feels that it is unique in comparison to his relationships with other suppliers. He also feels that 123Insight’s regular Open Days are useful, as they provide an open forum for discussion and allow customers to swap ideas; “I don't think we get this from any other suppliers. We go to the 123insight Open Days, we meet other users of the system and hear what they are doing with the system. It gives you other ideas of how you can improve. I don't think this approach is seen with other companies. There's never that meeting of like minds.”

MKP plans to implement 123insight’s CRM+ in the future to assist the sales department. Adrian feels that 123insight’s stable platform coupled with its attractive business model has been instrumental in the success of both businesses. He concluded; “123insight is the quiet thing that just runs in the background. The interesting thing is that after the successful implementation at Maine, when MKP wanted to look at an MRP system we started off with the projects and then moved onto implementing it across the whole company. We didn't even go elsewhere - straight away the decision was that we'd go with 123insight.”

Find out more

If your company is experiencing similar problems to this case study customer, why not talk to us about how 123insight could be a good fit for your business. There's no commissioned sales people, so no hard sell - just an educational approach to helping you understand what MRP should be doing for your business.

Complete this form to find out more.